Environment

ENVIRONMENT

Aiming for a Sustainable Global Environment for Our Children

FY25 Environmental Policy

Six Environmental Goals

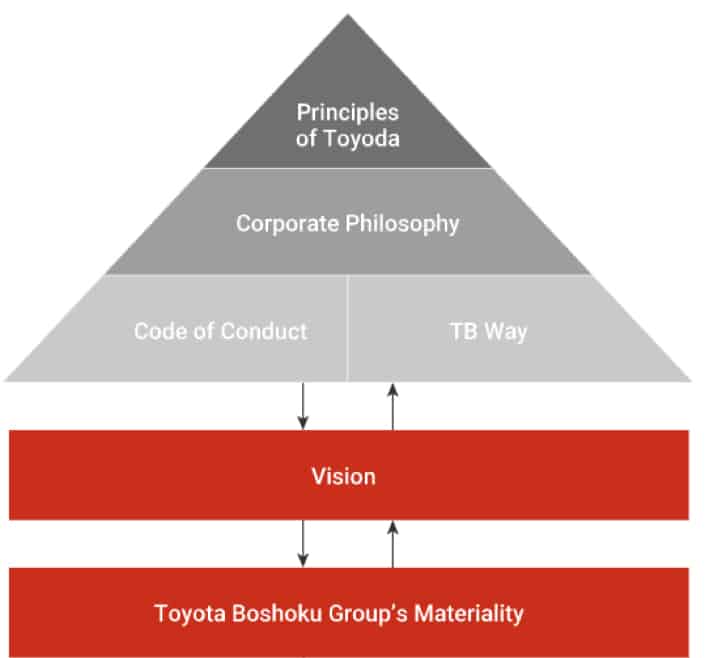

Vision

We will work together with all stakeholders with the aim of creating a sustainable global environment where children can lead their lives with a smile.

2025 Environmental Action Plan

As an Interior Space Creator, we will contribute to people’s quality of life, creating comfort, safety, and reassurance through innovation

Using our established technical capability, we will contribute to realize a society with no traffic casualties through providing products that assure safety

We will develop people capable of contributing to society, who have diverse values, a challenging spirit and understand the value of strong teamwork

We will continue to be a company of integrity trusted by all our stakeholders, inheriting our tradition of fairness and moral behavior to the next generation

SAFETY AND HEALTH

Basic Philosophy for Safety and Health in Toyota Group

- Safe work

- Reliable work

- Skilled work

- Safe Work is “the gate” to all work

- Let us pass through this gate

Message from Eiji Toyoda

since 1957

Basic Philosophy for Safety and Health in Toyota Boshoku Group

To foster a corporate culture that places the top priority on a safety, we declare that

- manufacturing things,

- handling things,transporting things,

- and disposing of things

will only be carried out when we can secure safety, health and appropriate environments for people to do the work. In addition, we conduct based on the following ground rules.

Message from Shuhei Toyoda

since 2005

FY2022 Safety and Health Policy

“ Build a Mutual Enlightenment-Based Safety & Health Culture ”

SAFETY AND HEALTH

Promotion of Safety and Health activities

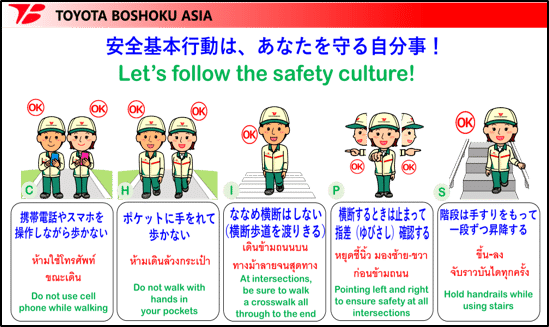

In order to prevent occupational accidents, we believe it is important to foster good manners and morals among company members, and by doing so foster a culture where safety rules are followed instinctively. As part of our efforts to do so, we continuously enforce the Toyota group-wide “Po-ke-te-na-shi (CHIPS)” policy.

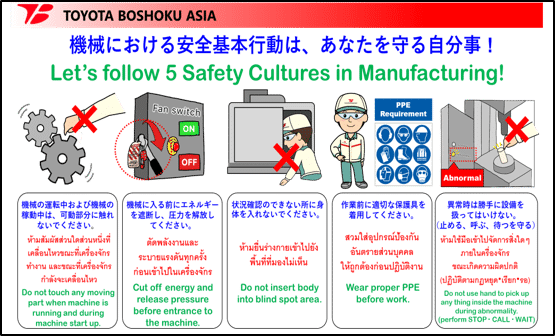

Safety culture (CHIPS)

5 Safety culture in manufacturing workplace

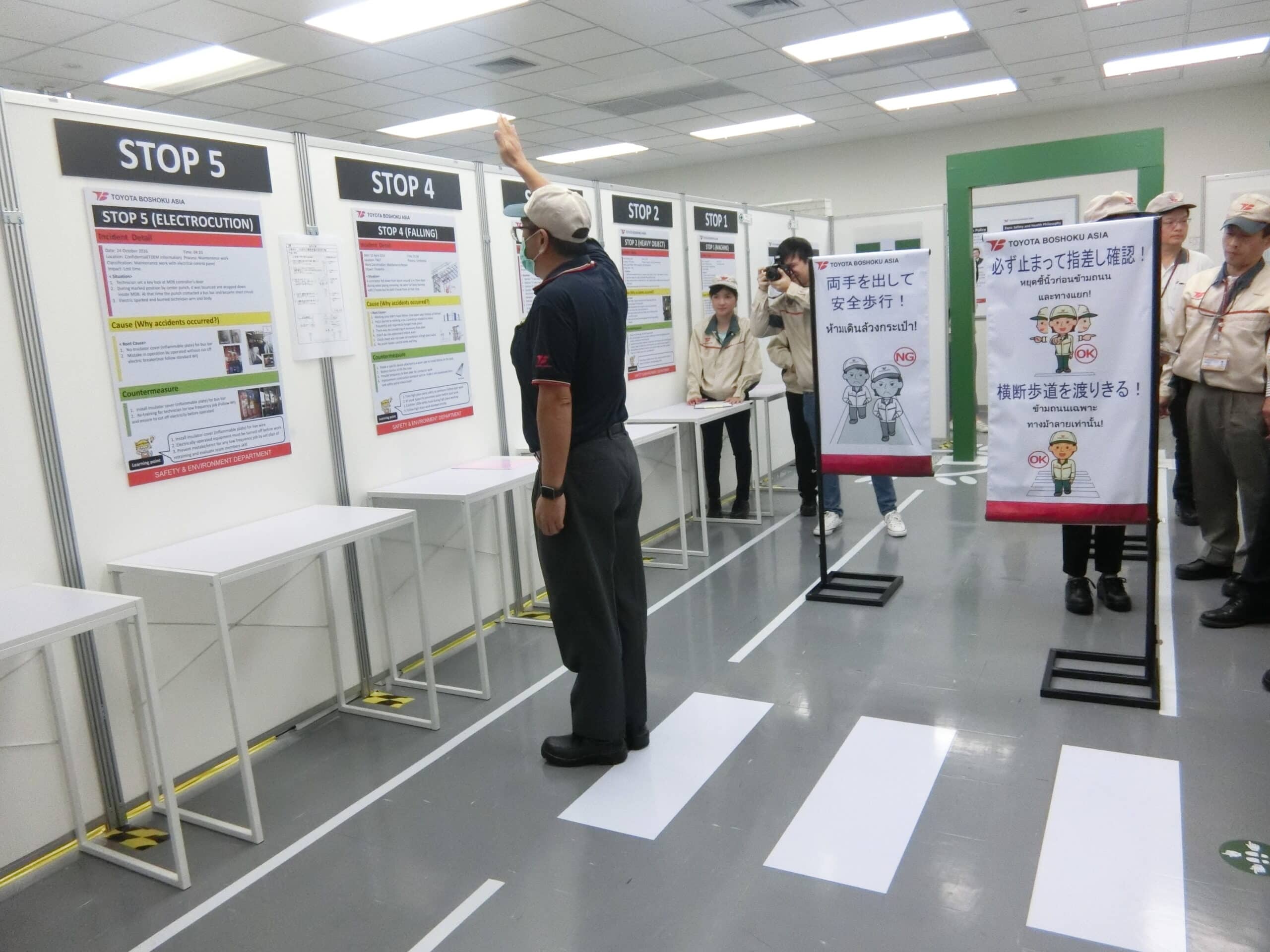

Safety Dojo

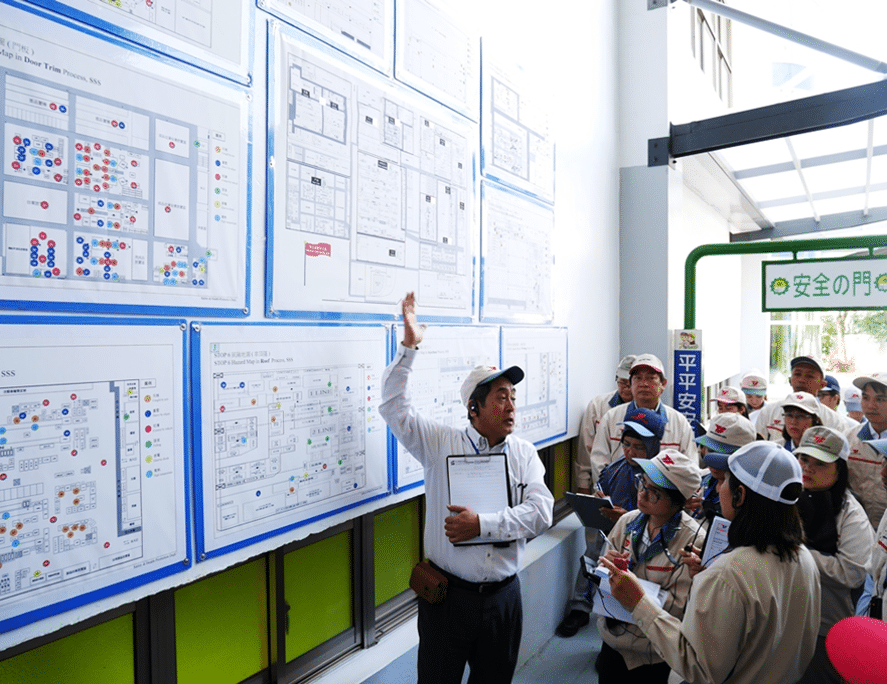

Safety Dojo is a TB group's standardized practice activities to increase safety awareness according TB Asia standard such as safety regulation, STOP6, safety culture, KY meeting, Fire prevention, High place work and etc.

Safety driving activity

Furthermore, we have provided the safety driving activity to promote and emphasize all employees to prevent the traffic accident in long holiday.

Fire safety inspection by Top management

Fire accident is serious situations that we don’t want to happen. Therefore, we have provided the fire safety inspection by Top management 2 times/year in Apr & Dec to find out the fire risk in the workplace and take countermeasure in order to prevent fire accident.

Fire safety knowledge

In order to prevent fire accidents and follow Thai safety law requirements, we have provided the fire knowledge and practice to all employees every year such as Basic fire fighting, fire drill & fire evacuation every year.